What is IR+ADIA?

In painting processes, the IR+ADIA system is the revolutionary and ingenious application synthesis of two widely consolidated technologies, for the first time together: infrared radiation and adiabatic cooling.

Compared to traditional paint curing systems with hot air ovens and ventilated cooling tunnels, IR+ADIA guarantees the following benefits:

- reduction in painting time cycle

- production increase

- space reduction in the painting area

- energy saving, in compliance with the guidelines of governments on sustainability

- noise reduction, health and safety

- flexible processes and fast order change

- better quality and treatment resistance

- constancy and repeatability of the final result

How does IR+ADIA work?

IR+ADIA is the first system that combines infrared curing with adiabatic cooling, fully exploiting its synergistic potential and generating advantages previously unimaginable in industrial painting processes.

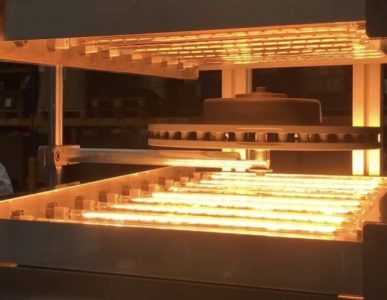

IR Curing:

Through infrared emitters, IR+ADIA gives directly to the painted piece the necessary energy being sufficient to trigger and accomplish paint crosslinking, whether it might be primer, water-based enamel or solvent-based enamel applied on metallic or non-metallic surfaces.

Transiting directly from the source to the painted piece, energy is not dispersed, unnecessarily heating the air or the oven itself.

The IR oven also allows to reduce maintenance times and costs, as there are no additional components – such as pipes, exchange coils, filters nor gaskets – which need operators to intervene constantly.

Adiabatic Cooling:

With IR+ADIA, cooling process of the painted piece is obtained by directing charged air with atomised water directly onto it. That mixture, denser than ‘normal’ air, has greater power to remove thermal energy.

As it happens in the curing phase, even the ‘cold’ thermal charge necessary for cooling is concentrated and affects only the treated piece, allowing targeted action.

“Easy, everyone can do it!”

DON’T DO THIS AT HOME

IT’S ALL ABOUT THE RIGHT ENERGY POWER for a specific object to be painted.

Many have tried without obtaining the desired results and with a useless waste of time and economic resources. Movingfluid, through studies, tests and lab analysis has developed specific expertise to guarantee the maximum effectiveness of the IR+ADIA system, to be custom-made according to process variants.

Do you want to quantify the benefits of IR+ADIA in your system?

Efficiency in production cycle and quality

Inserted within company production processes, the IR+ADIA system offers essential savings:

- Energy savings

- Spaces reduction

- Cycle time reduction

Those results were achieved aiming at a single goal: making the curing and drying process sustainable from every point of view. Therefore, provide sufficient energy in a targeted manner, without dispersions and increasing the yield compared to traditional crosslinking or polymerising systems. Depending on the system, those advantages may be present individually or simultaneously.

In detail, IR+ADIA guarantees the maximum production cycle yield thanks to:

1. Energy savings

Traditional ovens are energy intensive. By their very conception, they present inevitable thermal dispersions. In convection ovens, it is in effect necessary to heat a whole series of components: burners, exchange coils, pipes, walls. In turn, those parts disperse energy into the environment, if not externally. How many resources are wasted?

Thanks to the use of infrared lamps, the IR+ADIA technology uses only the fuel aimed at generating the energy useful for the process, transmitting it only to the painted piece.

Convection can also dissipate energy in the machining transition from large components to smaller parts. On the contrary, IR+ADIA guarantees flexibility and no machining ‘inertia’.

2. Spaces reduction

With IR+ADIA, the plant areas occupied by the heating and cooling stations are considerably reduced, occupying approximately 1/4 or 1/3 of the space normally dedicated to convection.

That is especially real in automatic air transport systems. The lengths of ovens and cooling tunnels are in effect proportional to paint drying time and transport speed or to the takt-time of the various phases in line.

With IR+ADIA, exposure times are reduced and, consequently, the whole line is more compact.

In the revamping of existing automatic systems, that advantage cannot of course be fully exploited – considering that the line is mechanically already built – unless a layout redesign has been carried out.

3. Cycle time reduction

The strength of IR+ADIA is the ability to optimise the painting process in both phases that set it up:

- Dust-free curing time: IR+ADIA allows to minimise any defects due to surface filming. The reason is that infrared heating starts directly on the painted part rather than on the outermost of the painted layer, as it happens with hot air.

From a qualitative point of view, advantages are evident:- Total elimination of pinpoints and burns

- Reduction in the ‘orange peel’ effect, as the film has much time to unwind

- Completion of crosslinking. With IR+ADIA, the completion of crosslinking coincides with the end of curing. All means used – water or solvent – is in effect expelled during curing.

That eliminates the times normally required for drying, a phase which can take up to 72 hours with the traditional process. The painted pieces can be immediately handled and packaged, with a considerable reduction in storage areas.

A faster process and an unparalleled qualitative yield:- Total elimination of blistering defects, which could instead occur on a packaged object not having yet released all the residual moisture, as it often happens with the traditional curing process.

- The painted object, exposed for a shorter time to radiation, accumulates less heat in depth. Internal components, such as seals and oils or greases, are therefore exposed to fewer critical issues.

All the benefits as reported above can be applied to your process.

Movingfluid’s technicians are at your disposal to quantify the real benefits thanks to IR+ADIA and specifically for your production line, answering all your questions. Our experts will put the acquired expertise at your disposal, concretely accompanying you towards the desired result.

With IR+ADIA, industrial painting is at a turning point.

Slow process, lack of space and poor quality were mishaps yesterday.

Today they are solutions.

Do you want to talk about it? Do you need to know more?