In this article:

- Hybrid engines: the Leak Test that detects leaks at every stage of construction

- Movingfluid Leak Test System: the luxury of simplicity

- Distinctive advantages of the new Leak Test system for hybrid engines

- Leak Test for hybrid engines: the stages of control

-

-

- Pre-assembly stage test

- Assembly stage test

- Inverter pre-assembly test

- Plate exchanger test

- Circuit testing and filling

-

-

-

- A free approach to leak testing

Hybrid engines: the Leak Test that detects leaks at every stage of construction

In the automotive industry, in order to test the tightness of an engine and ensure that it does not leak fluids, a Leak Test must be carried out to certify its suitability for installation on the vehicle and, ultimately, for road worthiness.

If a leak is found, the faulty engine will not be able to proceed to the next assembly stage, which would otherwise generate additional costs in terms of inspections, man-hours and waste generation, where, on the contrary, there should have been a profit.

If the Leak Test is failed, it then becomes a priority to identify with absolute precision what problem caused it. Faulty material, components, joints. Everything must be questioned. On a finished engine it is not easy to find the cause effectively and specifically.

On the contrary, a failed test of this kind, without further specifications, will generate uncertainty and concern about all the production stages that have been completed up to that point. The fear that other engines in the same batch might reveal the same problem, even over time, is entirely justified.

The repercussions in terms of reputation and brand reliability would be incalculable.

To all intents and purposes, a great misfortune for the producer. How to avoid it?

This is the challenge tackled by our problem solvers, who have developed a complete and modular Leak Test system that can also be applied to new-generation hybrid engines, capable of providing an accurate account of compliance with the quality and safety requirements of each individual engine component at every stage, preventing the inherent inconclusiveness of a single overall final result.

The tests we are talking about concern both the components used for electric motors, such as the inverter or plate heat exchangers, and the basic components of endothermic engines, such as the engine block, cylinder heads and intake manifolds, and are therefore universally applicable.

Built using the latest technology, Movingfluid’s Leak Test system is capable of expressly testing every stage of hybrid and endothermic engine construction, from pre-assembly to post-assembly, making it possible to identify the specific problem at every stage of construction.

Identifying problems in good time allows them to be addressed and resolved immediately, also preventing the error from being repeated in other parts.

It allows, in other words, to turn misfortune into an opportunity for improvement.

This not only concerns correction when a leak is detected. When the engine is finished, the Leak Test value questions several possible scenarios, whether positive or negative, leaving a certain level of uncertainty:

AS IS:

-

-

- The test goes wrong: you have to figure out which part is defective or the assembly error. How to trace the problem precisely when the engine is finished?

- The test goes well: efficiency of the engine overall is proven, without individual components and processes being analysed during assembly. When subjected to the stress of wear and tear from actual vehicle use, the weaker parts may give way and only then generate a noticeable leak. How to understand what broke down after commissioning? Too late. The vehicle is sent back. The engine has to be replaced.

-

TO BE:

The goal to aim for is a leak test that guarantees long-term reliability and long life for the engine overall, through preventive, specific and selective leak tests.

This is what Movingfluid has made possible today, thanks to the new complete modular Leak Test system for hybrid or endothermic engines developed by our problem solvers.

Movingfluid Leak Test System: the luxury of simplicity

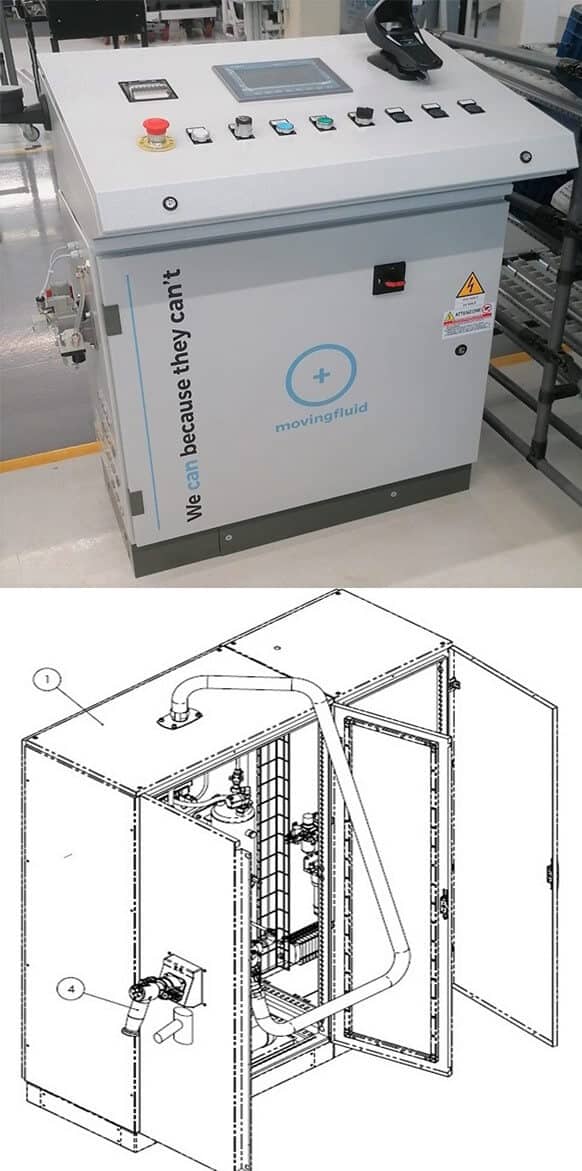

The new complete Leak Test system for hybrid and endothermic engines designed by Movingfluid differs from others on the market because it responds to a primary human need, as well as to technology: that of simplicity, an increasingly rare and sought-after value that can only be achieved by those who know how to create profound order. This is the meaning that Movingfluid associates to the concept of ‘Less is more‘, which is perfectly represented by this new leak detection technology.

In radical contrast to our competitors in the field of fluid handling, our high-precision machines aim above all to be essential, immediate, versatile.

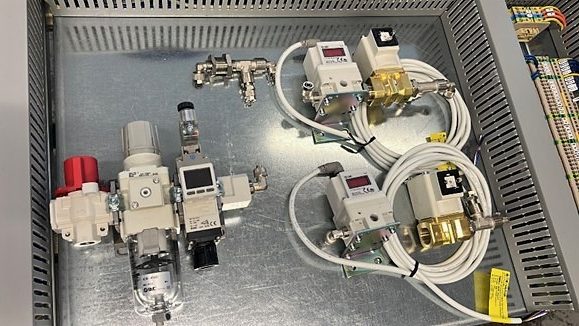

By carefully and consciously selecting the construction parts, we identify those components – and only those – necessary for the complete and precise operation of the entire asset, exploiting their full potential.

Building a high-performance yet simple Leak Testing system means having capable engineers behind you, supervision of the most up-to-date technology on the market, a keen eye for cost sustainability, excellent testers and skilled installers. It takes perfect knowledge of what lies behind it.

At Movingfluid, we have and make all of this available to our customers.

Lack of clarity, confusing information, difficult use are always a pain to solve.

Movingfluid has solved it for good.

Distinctive advantages of the new Leak Test system for hybrid engines

Here are some of the advantages of the new modular Leak Test system for Movingfluid hybrid and endothermic engines. Apart from hybrid-related components, all tests can in fact be applied to conventional endothermic engines:

-

-

-

- reliability and accuracy of detection: the test provides very high-precision data, and we certify its correctness

- greater reliability of the entire production process: the progressive verification of tightness data in the construction stages ensures the timely detection of a problem, in time for its correction, avoiding repercussions at production line level

- versatile and fully customisable: thanks to the modularity of this system solution, you only choose the functions you need. Our Leak Test system is not only aimed at the luxury sector or large companies. With us, simplicity is a luxury within everyone’s reach

- maintenance and assistance jobs reduced to zero, thanks to the great simplicity. We have not changed a single valve in the systems installed to date. If you want to knock us over, tell us otherwise

- user-friendly: intuitive use and easy-to-read analysis reports. This means less time lost in understanding operation and excludes any possibility of errors in interpretation

- fulfilment of all Industry 4.0 requirements: the highly technological set-up of the Movingfluid systems gives the system characteristics of high automation, data availability and readiness for integration with the company’s industrial process. This makes the following possible:

-

-

- pursuing efficiency and continuous improvement objectives

- modularity of scheduling, monitoring consumption, reporting, forecasting

- resetting errors

- reducing plant downtime

- accessing funding for technological development

-

-

- easy installation: the Leak Test system is a compact, unobtrusive machine: a metal cabinet-type container to be installed inside the plant, already fully assembled, tested and ready for use, without any interruption to the normal processing cycle

- customisable look: Movingfluid is a master of customised products that are functionally and visually aligned with existing products. This is an unavoidable requirement for many manufacturers – in automotive and other sectors – for whom machine configurations and aesthetic parameters are not a free choice, but respond to precise company guidelines. We have discussed this in detail here

-

-

Leak Test for hybrid engines: the stages of the check

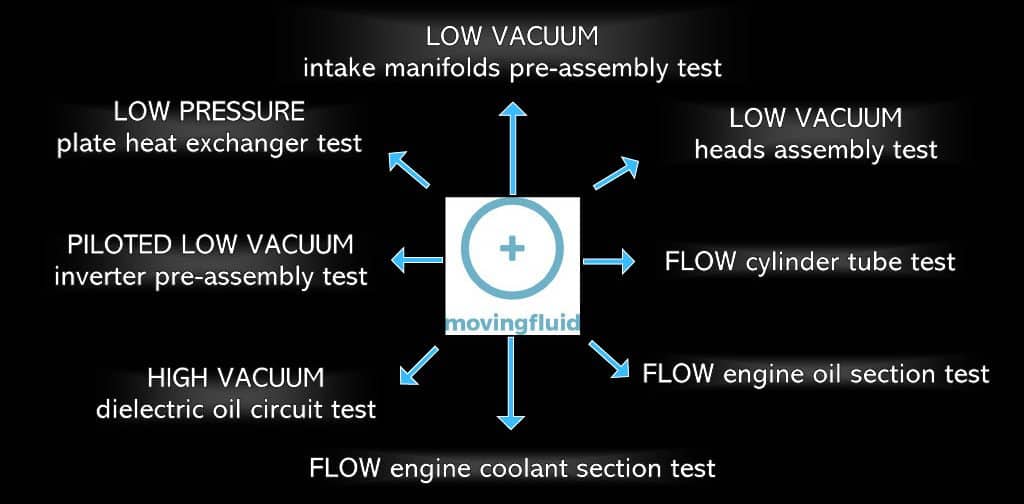

The complete Movingfluid Leak test system consists of several stages, each of which can be autonomous and independent of the others. That is why we speak in terms of a complete and modular system.

This means that each manufacturer is free to choose only the functions they consider useful for their own system. Just as you may decide to implement them all, perhaps gradually, depending on your needs and budget.

Here are all the stages in detail.

Pre-assembly stage test

The Movingfluid Leak Test system is able to test whether the pre-assembly stage has been performed correctly through the following tests:

-

-

-

-

-

- LOW VACUUM intake manifolds pre-assembly test

- LOW VACUUM cylinder heads pre-assembly test

-

-

Assembly stage test

The Movingfluid Leak Test system is able to test whether the assembly stage of the tubes has been carried out correctly through:

-

-

-

-

- FLOW cylinder tube test

- FLOW engine oil section test

- FLOW engine coolant section test

-

-

-

Inverter pre-assembly test

The Movingfluid Leak Test system can test whether the pre-assembly stage of the inverter has been performed correctly:

-

-

-

-

-

- PILOTED LOW VACUUM inverter pre-assembly test

-

-

-

-

Plate exchanger test

The Movingfluid Leak Test system can test whether the plate heat exchanger has internal faults:

-

-

-

-

-

- LOW-PRESSURE plate heat exchanger test

-

-

-

-

Circuit testing and filling

On the assembly line, all of the following components are assembled in the car with the various circuits, tanks, pumps and control units, through:

-

-

-

-

-

- HIGH VACUUM testing and filling of the dielectric oil circuit

- HIGH VACUUM testing and filling of the brakes oil circuit

- HIGH VACUUM testing and filling of the engine coolant circuit

- HIGH VACUUM testing and filling of the power steering oil circuit

- HIGH VACUUM testing and filling of the cabin AC and batteries

-

-

-

-

To perform filling, the circuits must be tested and made fit for this operation. The macro-stages checked by the complete Leak Test system for Movingfluid hybrid engines are:

1. Pressure drop test

This tests whether the circuit in the car has any missing or poorly assembled components. To do this, each circuit is pressurised to maximum operating pressure at different thresholds. A loss of pressure at this stage means that there is a major defect. If this stage fails, a re-work can be performed and the cycle repeated.

2. Vacuum test

The second stage is the vacuum phase. This control has two purposes:

-

-

-

-

- To check whether the circuit is completely sealed, especially brake oil and coolant gas. The system is capable of achieving high pneumatic vacuum values in the range of 2-3 millibars absolute.

- Generating a vacuum within complex, branched and hermetic circuits creates the conditions for filling the circuit with its own fluid.

-

-

-

If this stage fails, a re-work can be performed and the cycle repeated.

3. Filling

Once the previous stages have been successfully completed, we move on to actual filling. There are no pumps in our plants. The working tank is pressurised to the preset charge value. Communication to the car is then opened so that the fluids fill the circuits.

When these are full and the pressure stabilises at working pressure, you can move on to the next stage.

4. Levelling

The levelling stage involves extracting excess liquid from the circuit to ensure compliance with design specifications. This stage does not apply to gases, as dosing is done by quantity, using mass counters, with tolerances of a tenth of a gram.

A free approach to leak testing

Each stage of the Leak Test system for Movingfluid hybrid engines is autonomous and at the same time decisive in order to move on to the next step without any issues, with the certainty that each component is tight and that each procedure has been carried out correctly up to that point.

Choosing to adopt even one strategic control stage within your process will save you from production downtime and additional costs, and ensure greater reliability of your engines over time.

The modularity of the Leak Test system thus allows each manufacturer to freely choose their approach to engine control and how much they wish to invest.

A freedom of choice that, for Movingfluid, is always synonymous with respect.

Ranking top among the values that we always offer our customers.

Complete Leak Test system containers for hybrid and endothermic engines Want to get to know us?

-

-

- Airless painting [1]

- Alstom [1]

- ARO Ingersoll Rand [1]

- Atex diaphragm pump [1]

- Atex pumps [1]

- Automatic glue dilution [1]

- Automatic tissue machines [1]

- Automotive [8]

- Brembo [2]

- Case History [13]

- Cast iron brakes [1]

- Ceramic [3]

- Chemical [3]

- Chemical mixer [1]

- Chemistry [2]

- Cleaning [1]

- Cleaning industrial machinery [1]

- Dilution [1]

- Dosage [4]

- Dust [1]

- Electric diaphragm pumps [1]

- Electric double diaphragm pump [1]

- Extrusion [3]

- Finishing [1]

- Fluid handling [4]

- Fluids [2]

- Food [1]

- Freni in ghisa [1]

- Gases [3]

- Glue [2]

- Glue Dilution [1]

- Glue dilution for paper rolling [1]

- Henkel [1]

- Industrial paint booth [1]

- Industrial Painting [4]

- Industrial tile painting [1]

- IVECO [1]

- Know-how [2]

- Körber Tissue [2]

- Lamborghini [2]

- Liquid paint [1]

- Liquids [6]

- LPR [1]

- Market news [4]

- Mixing chemicals [1]

- Nikola [1]

- Oenology [2]

- Oil & Gas [1]

- Paint [2]

- Paint booth [1]

- Paper [2]

- Paper converting [1]

- Paper industry [2]

- Pneumatic powder conveying [2]

- Polcart [1]

- Powder Coating [1]

- Powder conveying [2]

- Powder conveying pumps [2]

- Powders [1]

- Pump test bench [1]

- Raw material producer [1]

- Saipem [1]

- Spraying [5]

- Streparava [1]

- SuperSix [1]

- Synthesis Spa [1]

- Tile [1]

- Tile painting [1]

- Tissue [3]

- Tissue converting [3]

- Tissue converting machines [1]

- Tissue glue dilution [1]

- Tissue industry glue mixing [1]

- Tissue machines [1]

- Toscotec [1]

- Trail [1]

- Transfer [7]

- Verniciatura industriale [3]

- Vortex hydra [1]

- Wood paint booth [1]